Preservation

Save The Terpenes

There’s something about the aroma of cannabis that soothes the mind and body. What are cannabis terpenes? Secreted in the same glands that produce cannabinoids like THC and CBD, terpenes are aromatic oils that color cannabis varieties with distinctive flavors and play a key role in differentiating the effects of various cannabis

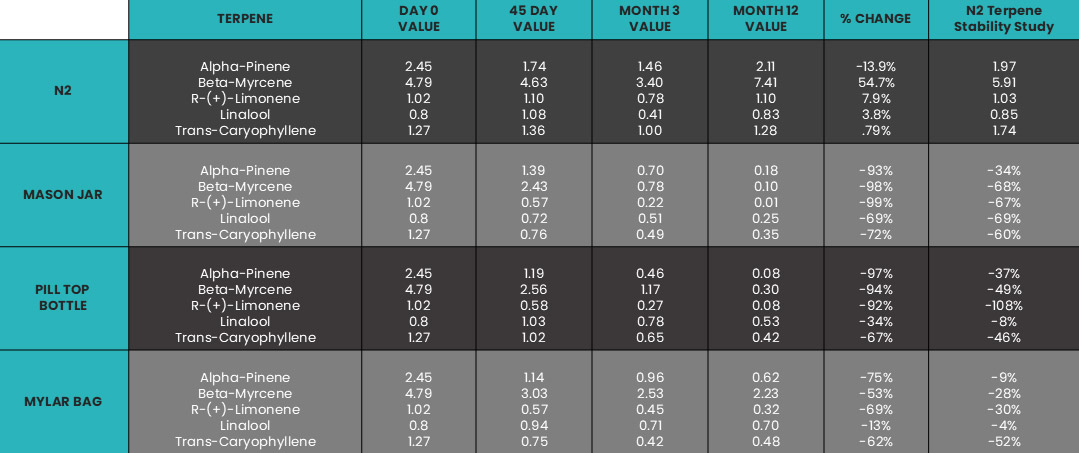

strains. Some terpenes might promote relaxation and stress relief, while others potentially promote focus and activity. Cannabis growers agonize over their perfect terpene blend, but what happens once the product is packaged? In a third-party study, N2 is proven to preserve the overall terpene profile, keeping your product fresh like the day it was packaged.

Terpenes Stability Study

Additional Considerations

Material Quality

N2’s cans are lined to protect terpenes and to prevent leaching. The quality of packaging is crucial when it comes to maintaining the quality of the product being packaged. N2 offers food-grade lined cans that are designed to store heavily acidic compounds such as terpenes. Cans provided through N2 meet U.S. FDA regulations for articles intended for use in contact with food.

Storage Temperature

Packaged cannabis is sensitive to temperature, and extreme conditions can affect the quality of the product. N2 recommends storing packaged cannabis at a consistent and acceptable temperature (ideally between 32-68°F). Independent tests have indicated optimal storage temperature occurs at 58°F.

Humidity

The ideal relative humidity (RH) range for a packaging operation room is between 55-62%. This range inhibits mold growth yet guarantees product quality and resin integrity. A well-balanced moisture content in the immediate atmosphere will keep product fluffy, aromatic, and potent prior to packaging. N2 recommends monitoring humidity in the packaging facility.

Water Activity (aW)

According to U.S. FDA food packaging guidelines, a food at any pH that is not a Time/Temperature Control (TCS) food that is packaged with a water activity less than or equal to 0.92 will not support growth of clostridium botulinum spores. N2 recommends a water activity level of less than 0.65 for their packaging process.